Start Building with Mendix For Free

Build enterprise-grade web and mobile apps at speed with Mendix application development software.

Manufacturing Execution System, or MES for short, is a comprehensive and dynamic manufacturing system that monitors, tracks, documents and controls all phases of a production process, from raw material to finished product.

MES software acts as a connecting layer between PLM, ERP systems (IT) and machines (OT). This software layer optimises the efficiency and quality of the production process, leading to increased productivity and profitability.

The size of your factory does not matter. The right Manufacturing Execution System (MES) provides digital support and assurance of the production process for every shopfloor.

/Rolls-Royce-Logo-White.png)

/BAE-Systems-Logo-White.png)

MES software is at the heart of your manufacturing business, where all the data surrounding the production process comes together. With this data, you can improve the production process in a targeted way and strive for operational excellence. To achieve operational excellence, it is essential to get a grip on customer satisfaction, employee satisfaction, commercial impact and raw material use efficiency. Below are a few benefits of MES software that can support you in this optimisation drive.

MES software is at the heart of your manufacturing business, where all the data surrounding the production process comes together. With this data, you can improve the production process in a targeted way and strive for operational excellence. To achieve operational excellence, it is essential to get a grip on customer satisfaction, employee satisfaction, commercial impact and raw material use efficiency. Below are a few benefits of MES software that can support you in this optimisation drive.

Because quality information is transmitted and analysed in real time from the shopfloor, production companies can react reactively, preventively or even predictively to potential quality problems in the production process. In addition, quality measures are enforced during execution, ensuring even higher quality assurance.

With MES software, you can create a realistic production schedule that takes into account the availability of personnel, materials and equipment. By integrating planning and maintenance into these schedules, you can benefit from an optimal production flow and efficient use of resources. This contributes to higher uptime and improves the overall effectiveness of your equipment Overall Equipment Effectiveness (OEE).

An MES system tracks the entire production cycle so that the final parts or batches are enriched with the right production data. This data makes it easier for you as a manufacturer to comply with industry requirements or national regulations.

Storing data digitally offers opportunities for easy learning from this data. MES systems help operators execute the production process efficiently with digital tools such as work instructions, checklists and the ability to log issues digitally.MES systems can even provide proactive or predictive notifications based on data from Internet Of Things sensors on existing production machines. This allows even older machines to be seamlessly integrated into your Manufacturing Execution System.

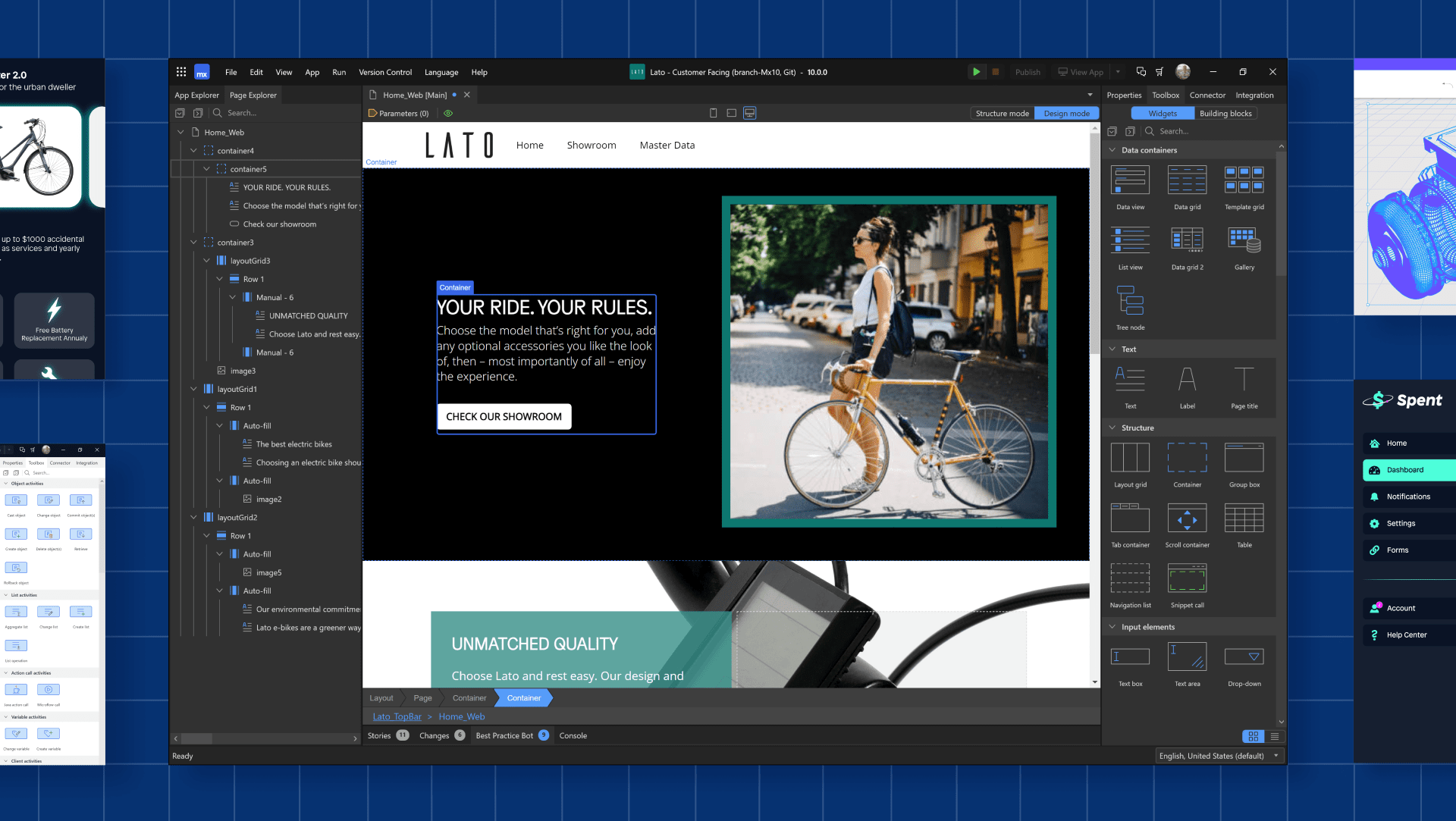

Mendix enables rapid, low-code customization of a MES, allowing manufacturers to tailor workflows, user interfaces, and logic without complex coding. This flexibility accelerates deployment, simplifies integration with existing systems, and adapts MES to specific operational needs.

A MES connects with Teamcenter to ensure a seamless flow of product and process data from engineering to execution, enabling full traceability and faster change management. Mendix enhances this integration with low-code customization, making it easier to adapt MES workflows to specific business and system requirements.

A MES seamlessly integrates with SAP to connect shop floor operations with enterprise resource planning in real time. This alignment ensures accurate production data, improved traceability, and faster decision-making across the entire manufacturing process.

Boomi connects a MES with enterprise systems like ERP, PLM, and IoT platforms through scalable, low-code integration. This ensures real-time data flow across applications, streamlining operations and enabling faster, more informed decision-making on the shop floor.

An AI assistant enhances a MES by providing real-time insights, predictive analytics, and intelligent recommendations directly within the production environment. This supports faster decision-making, reduces downtime, and helps optimize quality and efficiency across manufacturing operations.

Mendix enables rapid, low-code customization of a MES, allowing manufacturers to tailor workflows, user interfaces, and logic without complex coding. This flexibility accelerates deployment, simplifies integration with existing systems, and adapts MES to specific operational needs.

A MES connects with Teamcenter to ensure a seamless flow of product and process data from engineering to execution, enabling full traceability and faster change management. Mendix enhances this integration with low-code customization, making it easier to adapt MES workflows to specific business and system requirements.

A MES seamlessly integrates with SAP to connect shop floor operations with enterprise resource planning in real time. This alignment ensures accurate production data, improved traceability, and faster decision-making across the entire manufacturing process.

Boomi connects a MES with enterprise systems like ERP, PLM, and IoT platforms through scalable, low-code integration. This ensures real-time data flow across applications, streamlining operations and enabling faster, more informed decision-making on the shop floor.

An AI assistant enhances a MES by providing real-time insights, predictive analytics, and intelligent recommendations directly within the production environment. This supports faster decision-making, reduces downtime, and helps optimize quality and efficiency across manufacturing operations.

MES Light offers a fast, flexible route to digitising your production. It integrates easily with existing systems, providing rapid insights into your processes and enabling quick optimisations. When combined with Management Consulting and Data & Analytics services, it accelerates your digital transformation.

With over 40 configurable modules, MES Light is highly adaptable, start with a standard setup and scale as needed. Built on the Mendix platform and compatible with various ERP systems, it supports seamless customisation to match your unique production workflows.

Together, ERP, PLM, and MES form a unified digital backbone that covers everything from finance and procurement to production logistics and supply chain visibility. This ecosystem can be expanded further through integrations with other OT and IT sources, such as Bill of Materials portals, enabling more accurate forecasting across sales, resource planning, and production.

While ERP helps determine what to produce, MES takes that input and connects it to real-time factory data, showing how to produce it more efficiently, with less waste and greater profitability.

Smart manufacturing uses cloud connectivity and IIoT to enable systems, equipment, and products to communicate and optimise production autonomously.

MES plays a central role by connecting the digital (IT) and physical (OT) layers. With real-time data from connected devices and cloud integration, manufacturers can monitor, adapt, and improve operations from any location.

Build enterprise-grade web and mobile apps at speed with Mendix application development software.

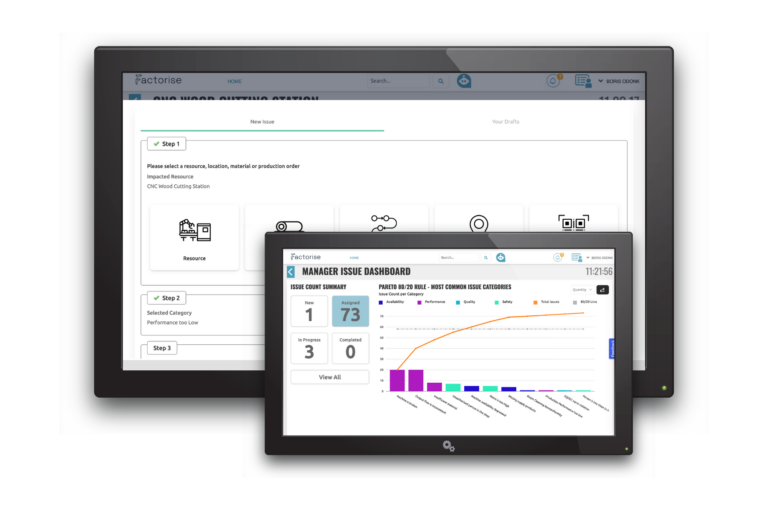

Factorise is a next-generation, modular MES solution built on the Mendix Low-Code platform, designed to accelerate digital transformation in manufacturing. By connecting IT and OT, the Factorise platform enables real-time data capture, faster decision-making, and continuous process optimisation across the shop floor.

With ready-to-deploy apps for lean manufacturing, issue resolution, and production performance monitoring, Factorise empowers manufacturers to reduce waste, improve efficiency, and scale smart manufacturing initiatives with speed and flexibility.

BAE Systems

ONVZ

VolkerWessels partnered with Emixa to implement advanced data platforms, enhancing project insights and decision-making.

Hanab collaborated with Emixa to implement a new cloud-based ERP system, optimizing operations and sustainability.

VORM engaged Emixa to enhance project control and efficiency in affordable housing developments through digital solutions.

A Manufacturing Execution System, or MES, is a comprehensive and dynamic system that monitors, tracks, documents and controls all steps of a production process, from raw materials to finished goods.

Mendix comes with connectors for Teamcenter and Siemens’ Industrial IoT ecosystem — so you can securely access and interact with PLM data without heavy lifting.

Overall Equipment Effectiveness (OEE) can be improved by optimising machine availability, performance and quality.

This starts with identifying and minimising downtime through regular maintenance and quick breakdown analysis. It is also important to analyse production processes and eliminate bottlenecks so that machines can run at their optimal speed.

If you have a complex production process, this can be challenging. Our Management Consulting and Data & Analytics colleagues are happy to help you optimise towards operational excellence.

A Manufacturing Execution System, or MES, is a comprehensive and dynamic system that monitors, tracks, documents and controls all steps of a production process, from raw materials to finished goods.

MES Light provides an efficient and flexible solution for manufacturing companies looking to optimise their processes without the complexity of traditional systems.

MES Light enables manufacturing companies to make adjustments even faster and manage their production environment more effectively.

Emixa's partership with Factorise enables us to deliver a composable Cloud MES solution with 40+ modules that always suits the needs of your shopfloor.

Overall Equipment Effectiveness (OEE) can be improved by optimising machine availability, performance and quality.

This starts with identifying and minimising downtime through regular maintenance and quick breakdown analysis. It is also important to analyse production processes and eliminate bottlenecks so that machines can run at their optimal speed.

If you have a complex production process, this can be challenging. Our Management Consulting and Data & Analytics colleagues are happy to help you optimise towards operational excellence.