Customer Projects

At Emixa, we take pride in our collaborative journey with great, international brands. These esteemed clients have entrusted us with their long term partnership, vision and challenges, and together, we've achieved remarkable successes.

From 3 Weeks to 3 Days: How Kornelis Improves Lead-Time by 85%

Kornelis, a specialist in producing caps and closures, was preparing for its next phase of growth. Their goal was to make smarter, faster investment decisions to stay competitive, without relying on k...

.jpg)

Case Study: Vynova Group

Discover how Vynova improved SAP efficiency and standardised maintenance with role-based training, driving operational excellence across departments.

Jan De Nul Transforms Engineering Processes with Siemens NX CAD

Jan De Nul is a global leader in maritime and civil construction. To stay ahead in an increasingly digital world, Jan De Nul set out to modernise its design and engineering processes.

YouniQ Manufacturing: Rapid, Software-driven Production

With only two employees, the entire process at YouniQ is software-driven. This enables fast, cost-effective production without human errors. While a six-week lead time is standard in the market, Youni...

Digitizing Sustainability: Winst uit je Woning Scales Operations with Mendix and Emixa

Winst uit je Woning, the fastest-growing company in the Netherlands, partners with Emixa and Mendix for a dynamic IT upgrade. Streamlined processes, user-friendly forms, and efficient scalability mark...

Scaling a Dealer Ecosystem: How Emixa Used Mendix to Modernize Urban Arrow’s Dealer Portal

Urban Arrow transformed its dealer support with Mendix, creating a dynamic dealer portal for efficient communication, order management, and improved customer service.

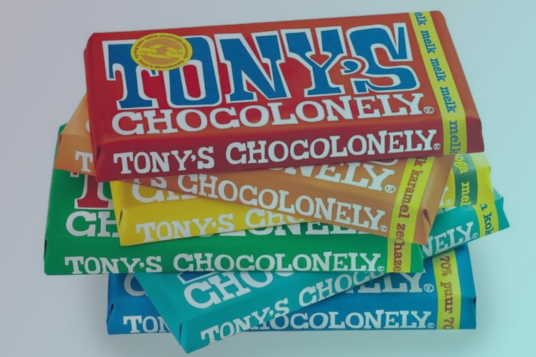

A Centralized iPaaS Solution for Tony’s: Emixa & Boomi Standardize Multisystem Data Flow

Tony’s Chocolonely partnered with Emixa to enhance transparency and efficiency in their supply chain, promoting ethical chocolate production

Tokamak Energy Accelerates Fusion Design and Manufacturing with Emixa‑Enabled Siemens PLM Platform

See how Emixa helped Tokamak Energy scale fusion technology development with tailored digital solutions, enhancing scalability and operational efficiency

Weener Plastics Maximises Logistics Efficiency with Emixa‑Built Transport Management System

Transforming with Mendix Low-Code. Weener Plastics optimizes logistics, reduces costs, and enhances global collaboration for sustainable growth