How RML Group Accelerated Innovation with Engineering Solutions

RML use their decades of experience and competitive prowess for powertrain and chassis development as well as concept vehicles and high-performance road and touring cars. Their in-house team has not only designed and developed some of the best performing race engines in the world, but also work for OEMs and specialist automotive suppliers. The company holds an impressive number of titles for the FIA World Touring Car Championships drivers’ and manufacturers’ titles, in partnership with Chevrolet in 2010, 2011 and 2012. The motorsports industry has high demands that RML must respond to quickly, this means the team must have the design, manufacturing and simulation tools to enable them to be flexible and make amendments in short timeframes.

Case study ERP implementation

One of the well-known construction companies in the Netherlands was in search of a new ERP system that would meet the company's needs. The current system was outdated and no longer capable of supporting the growing complexity of operations and processes within the company. There was a need for a system that was user-friendly, integrated, and specifically designed for the construction and infrastructure sector. Emixa was appointed as the implementation partner for the new ERP system.

How Modiform Revolutionized Its Supply Chain with Low-Code Innovation

Modiform, a family-owned business based in Leusden, specializes in developing and manufacturing products for the horticulture industry, including plant pots, transport trays, and packaging systems. As a forward-thinking product development company, Modiform is dedicated to continuously enhancing it's services and operations. Recognizing the increasing importance of technology in it's growth, Modiform has forged a strategic partnership with Emixa, a trusted ally in the pursuit of digital transformation. In collaboration with Emixa, Modiform embarked on several pivotal projects aimed at addressing key challenges in information provision, finance automation, and supplier relationship management. This case study delves into the innovative solutions implemented by Modiform and Emixa, showcasing the transformative impact on efficiency, accuracy, and overall business agility.

Case study Freeform Technology

Fractions of a second, microns of tolerance; in the exacting world of Formula 1® racing, triumph and failure are not far apart. With a background in that demanding environment, the two metalwork engineers who founded Freeform Technology in 2008 know the significance of meeting a specification exactly and delivering on time. Spotting a market opportunity to apply precision machining methods in the composites field, Simon Burchett and Fred Hutton founded the company in 2008 with one machine and some hand-me-down tools.

Medexs Proves It: You Can Implement S/4HANA in 3 Months

Medexs implemented SAP S/4HANA in 3 months with 3 tips from Emixa. It was a quick and efficient move for integrating processes, supporting market growth, and gaining a clear picture of the organisation.

LANXESS NV Brings Together Six Practices Into One Maintenance Process

LANXESS aims for uniformity in maintenance processes across six plants. Emixa helped with a three-phase improvement trajectory, resulting in a standardised work preparation process. The process leads to better collaboration, knowledge sharing and preparation for peak moments, and forms the basis for a permanent improvement process.

Jan Snel Lays the Foundation with SAP S/4HANA

Jan Snel implemented SAP S/4HANA in just 5 months to support further growth. Replacing outdated systems and using Emixa Prefab SAP software led to uniformity and user involvement. The company now has more control and insight into performance, making it ready for further growth and ambitious goals in the construction sector. The project was successful thanks to Jan Snel's 'can do' mentality and user involvement. Jan Snel Group is the market leader in modular construction solutions in the Benelux and offers permanent and semi-permanent housing in various sectors.

Case study Urban Arrow

Ten years ago, Urban Arrow started building e-cargobikes, and they have since become a familiar sight on European and American streets. The scale-up manufactures cargo bikes for transporting children and goods. In recent years, the ten-year-old company has experienced significant growth. To effectively serve the increasing number of dealers, Emixa and Urban Arrow built a new dealer portal. Thanks to this portal, dealers can better assist their customers and manage expectations more effectively.

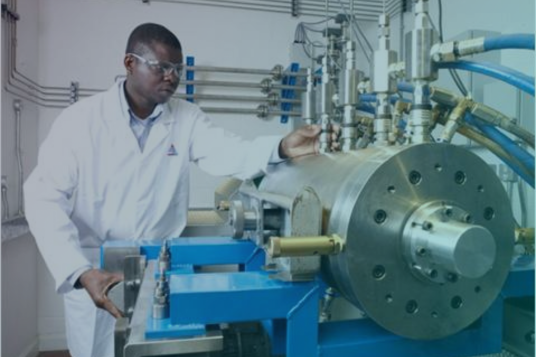

Casestudy AESSEAL

AESSEAL Plc, is a business founded on expertise that focuses on preventing liquids and gases from escaping into the environment. Millions of permutations can be assembled from stock and dispatched within 24 hours, and a database founded on decades of experience speeds the development of nonstandard products. AESSEAL now supplies customers in 104 countries. Stuart Welsh, head of IT explains.